Infill is a crucial component of synthetic turf as it will play a significant role in the turf aesthetic, feel, drainage and overall protection. But the primary purpose of infill is to help the fibres stand up or return to their intended upright position after hours of play.

In our third synthetic turf web series episode, our synthetic grass specialist Andrew Morrow explains the importance of choosing the suitable infill for a playable surface and gives an overview of the most used infills worldwide.

What is infill for synthetic turf?

We call infill what typically refers to the products placed between the synthetic turf's fibres, the equivalent of soil for synthetic turf.

It covers many roles, from protecting the synthetic turf's backing from UV rays to maintaining its look while mimicking the feel of natural turf.

There are many infills available on the market, but the four most used infills around the world are:

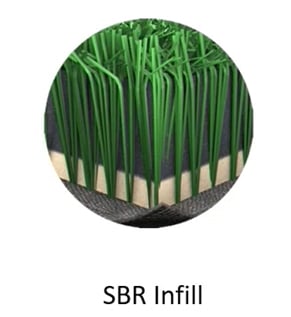

- Rubber crumb or SBR infill

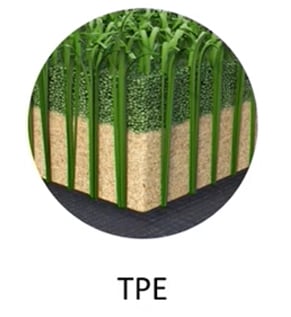

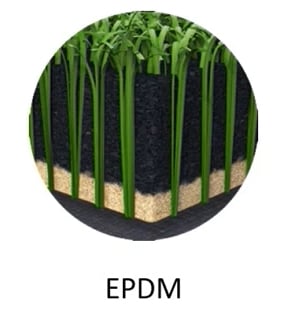

- TPE and EBDM

- Organic infill

Rubber crumb or SBR infill for the best cost-effectiveness ratio

From a cost-effectiveness point of view, this is the most economical infill on the market and has excellent playability. It has been predominately used in its original form as a black granule, however can be coated with a coloured polyethylene coating, ie green, red, blue etc.

TPE and EPDM infill for an elite surface

Both TPE and EPDM rubber infills are produced from virgin materials and come in different colours, which are often used in different sports ( Athletic tracks ) and playgrounds ( softfall bases )

There are many benefits in using rubber infills, however there is one drawback which is heat. Direct sunlight will heat the playing field, mainly due to the heat absorption of the rubber infill. It is interesting to note that there has been a claims that certain coloured rubbers provide a cooler playing surface. University testing of different coloured EPDM and SBR rubber infills under UV lights, has shown little difference between the temperatures they reach.

If we are using these infills, in conditions where temperatures are reaching over 30 degrees and above, then scheduling training and games before and after the hottest part of the day, would be a practical solution.

Organic infills for a synthetic turf sustainable approach

Different options exist when looking at using organic infill for synthetic turf.

The first option is a mix of Coconut husk and cork granules (approx 90% coconut / 10% cork). This combination may require the field to be irrigated, as the coconut husk fibres can breakdown, causing the drainage capacity of the field to be reduced.

Cork comes from cork trees and is seen as sustainable option; the outer bark is harvested every nine years. As the trees grow, it is possible to shave the outer husk (cork.) This is a fantastic option from a sustainability point of view!

The second option is cork itself. It is a great environmental solution as it can be reused in a new field or in landscaping applications (garden bed mulch).

Cork has it’s natural properties that helps the product breaking down (which is why they have been used in wine bottles for centuries).

The main benefit of using cork infill is the heat reducing properties. Cork can reduce the heat build-up in a synthetic field by 15 – 20 degrees when ambient temperatures rise above 30 degrees. As an example, Casey Field Regional Soccer facility has 4 fields. One natural, one with cork infill and two with SBR infill. Temperature readings when the ambient temperature was 30 degrees: Natural Field 25 Degrees, Cork Field 45 Degrees, SBR Fields 62 degrees.

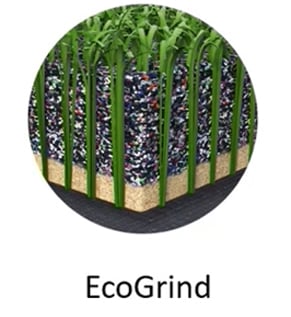

Other organic and sustainable infills that are being used around the world are: crushed olive pips and Ecogrind (repurposed/reused leftover rubber products from the manufacture of other products).

At the end of the synthtic sports field’s life, the infills mention above can be recycled/repurposed, as replacement infill for new fields or other uses.

For further information or questions/remarks on this topic, reach us now!

Return to the main blog page.